Bureau SEM Technologies Reveal Important New Insights in Rock Properties

The Bureau has long been at the forefront in the use of the scanning electron microscope (SEM) for the detailed characterization of rocks, and the two SEMs in its Scanning Electron Microscopy Laboratory are making groundbreaking discoveries at the nano scale.

The lab’s Zeiss Sigma microscope is a high-resolution SEM with automated large-area mapping capability for all its detectors, which makes it very attractive for many applications. Outside users are interested in many of its capabilities and have varied interests (element mapping of meteorites, biofilms in speleothems, zoning on overgrowths in zircons, titanium concentrations in quartz grains, and defect density in nanofilms for superconductors). From the Bureau, the Fracture Research and Application Consortium (FRAC) is the main user of the Zeiss Sigma. FRAC uses SEM imaging to elucidate the interaction between deformation and diagenesis in both outcrop and subsurface rocks. It focuses on identifying processes that systematically create and destroy fracture porosity and affect fracture size and distribution.

Two techniques using the FEI Nova NanoSEM have yielded significant new insights into mineralogical composition, rock textures, pore system architecture, and microfractures in rocks. Using this high-resolution field emission SEM combined with energy-dispersive X-ray spectroscopy and cathodoluminescence methodologies, Bureau scientists are gaining valuable new insights into depositional environments, diagenesis, fracture systems, and the geological conditions, processes, and resource distribution in hydrocarbon reservoirs. Enhanced by Bureau research, these two SEM processes have significantly impacted shale studies by illuminating rock characteristics imperceptible using traditional SEM technologies. The first, a process known as argon ion milling, shaves an extremely thin layer off of a sample of shale, making it clean and smooth for more-accurate SEM imaging of the surface. The resulting image reveals shale pore structures clearly for the first time and enables researchers to better understand rock properties.

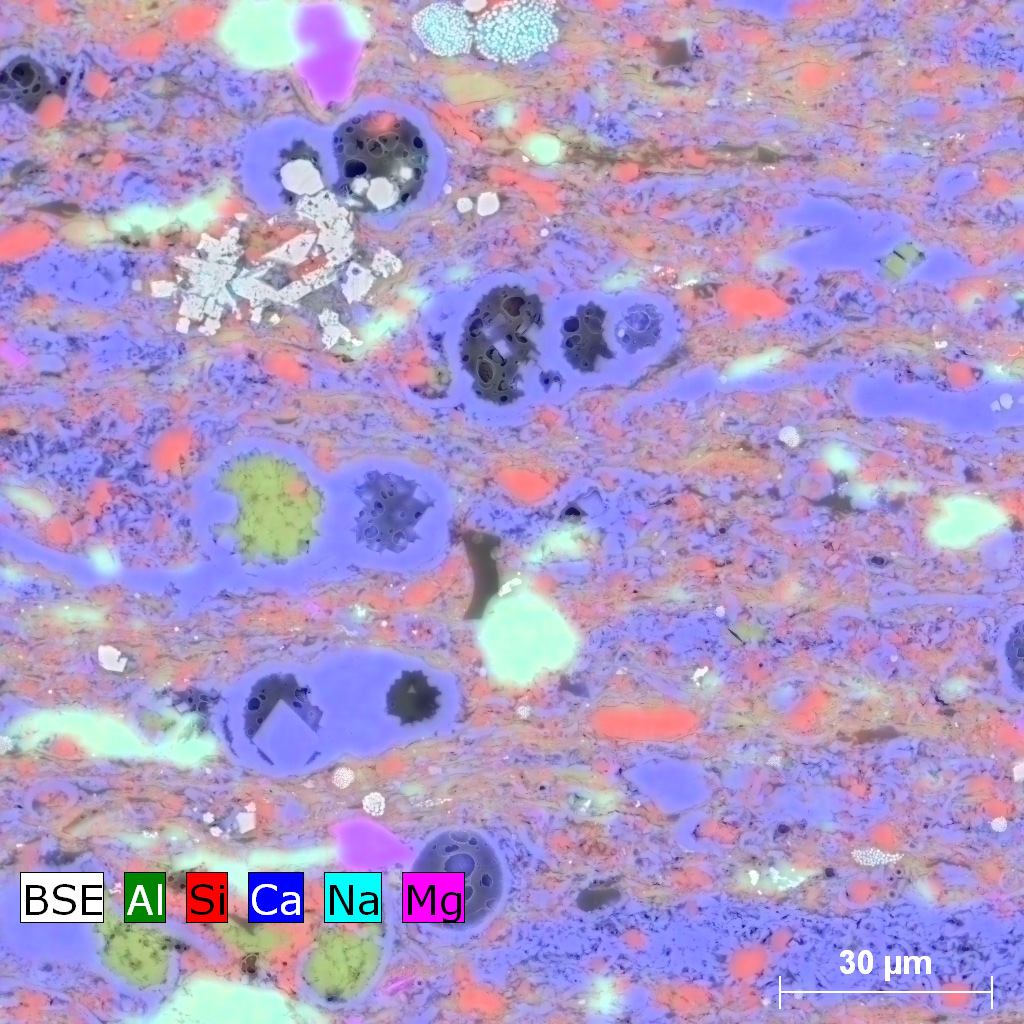

The second process, known as element mapping, makes it possible to see where rock pores are in relation to the mineral phases of shales. This characteristically varies in different rocks, so pore location provides key information regarding the various stages of maturation in different rock types. Recent research demonstrated the benefit of this method in identifying magnesium in shale samples. X-ray fluorescence (XRF) interpretations alone could not distinguish whether the mineral hosting the magnesium in the sample was chlorite or dolomite, but when false color was assigned to magnesium and added to an SEM image of a sample, the mineral hosting the magnesium could be easily seen and identified. This interpretation method has significant implications at a variety of scales, from microfractures, to fluid-flow studies, to reservoir characterization. The SEM Laboratory is a tremendous resource for the continuing study of the intricacies of rocks and rock processes at microscopic scale.

SEM image showing an Ar-ion-milled surface of the Eagle Ford Shale; image has been color coded to show elemental composition. Note the relatively large pores in the dark gray organic matter partially filling the foraminifera. In this image, blue is calcite, red is quartz, green is clay, purple is dolomite, and aqua is feldspar.